Downhole Tubulars

Downhole tubulars are manufactured using cutting edge technologies proven to produce

pipeline costruction that addresses various operating challenges and environments.

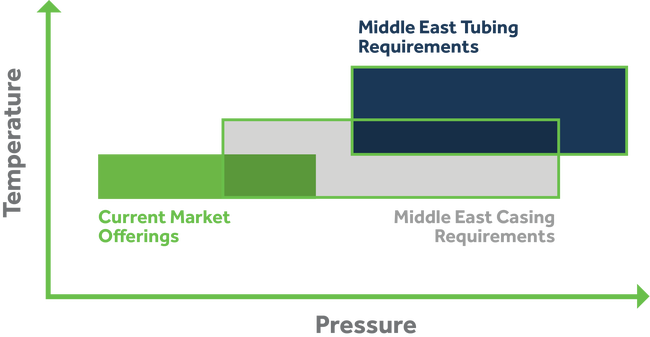

Current market offerings do not match the target Middle East operating conditions in steel tubing and casing for water, Oil and Gas applications.

There exists a gap between current market offerings and downhole tubular requirements in the Middle East, as shown in the below example figure.

This gap is bridged with a robust R&D development program to produce cost-effective and technically feasible non-metallic downhole tubulars. Novel will leverage the expertise of its parent companies, Saudi Aramco and Baker Hughes, in developing and deploying composite tubulars in onshore non-metallic pipelines, offshore subsea and downhole applications. Backed by a pool of consultants and experts, Novel is working on the development of tubulars for water, Oil and Gas application under various operating conditions of excellence in the Kingdom.

- Corrosion-free systems.

- Minimization of production interruption.

- High strength-to-weight ratio.

- Improved flow assurance.

- Possible logging through pipe body.

- Reduce/eliminate rig capacity requirement.

- Faster installation and reduced total cost of ownership.

- Reduced carbon footprint .

R&D Downhole Tubulars Process

1. To ensure these customer needs are addressed, the problem is defined, and challenges associated with current metallic technologies are identified such as internal and external corrosion, scaling, extended reach casing deployment and logging in observation wells across casing. A holistic techno-economic feasibility study is firstly completed, including assessment of the tubular and its qualification ecosystem, assessment of the connections, as well as a life cycle assessment of the system risks and developments for the needed system components.

2. Through operational best practices of Saudi Aramco and the upstream experience of Baker Hughes, system challenges are investigated and a mitigation plan is put into action. System challenges include those in different phases from manufacturing through to logistics, drilling and deployment, completion and well testing, injection/production, logging, inspection and intervention until well and tubular end of life.

- Drilling.

- Deployment.

- Production and injection.

- Connection and completion.

- Logging and intervention.

- Deployment and manufacturing.

- Operational practices.

The Novel parent companies’ diverse portfolio of non-metallic composite solutions and extensive pool of complementary backgrounds and expertise enable the mitigation of associated system risks in a systematic and robust program.

3. Downhole tubulars are designed with carefully selected materials using state-of-the-art proprietary design tools, simulation software and design optimization workflow. Composite failure theories and failure modes are understood and investigated using the Novel partnership's parent companies’ experience of downhole conditions and modelling/simulation expertise. Consequently, pipe and connection failure envelopes are generated and matched with downhole loads and conditions, while targeting premium, cost-effective designs. The product is targeted towards broad market adoption for Middle East (MENA Region) customers operating in high temperatures and harsh conditions.

4. Manufacturing excellence established Novel's parent companies as market leaders in manufacturing and deployment of onshore and offshore flexibles, and leveraging such expertise is key for downhole tubulars development. The downhole tubulars are manufactured using cutting edge technologies proven to produce pipeline construction that addresses various operating challenges and environments.

R&D prototypes and nal products are extensively trialled in lab, yard and field using Baker Hughes, Saudi Aramco, academic and industry partners’ facilities. This knowledge and these R&D programs will be localized in Novel’s state-of-the-art R&D facility and world-class testing labs in SPARK.

5. The result is downhole tubulars with higher specs than the current market offerings, substantial cost-saving for customers, improved well integrity and safety, as well as reduced environmental risks.

Novel is keen on understanding the customer's interest in these tubulars to steer these developments in a

customer-centric approach. To partner with us, click here.